Hello, everyone, if you want to customize your brand clothes with a China garment factory.Today, we gonna show you the most important experience:

We have rich experience in sourcing clothes suppliers in Guangzhou China.

The clothing production process can be summarized as design-pattern-sample- order-production-quality inspection.

Let’s talk about each link in detail.

- Apparel Design

The three elements of clothing design: style (theme and skeleton, which is the basis of clothing modeling), color (the main color that creates the overall visual effect of clothing), and fabric (the basic material that reflects the style, and different materials are used to reflect different styles).

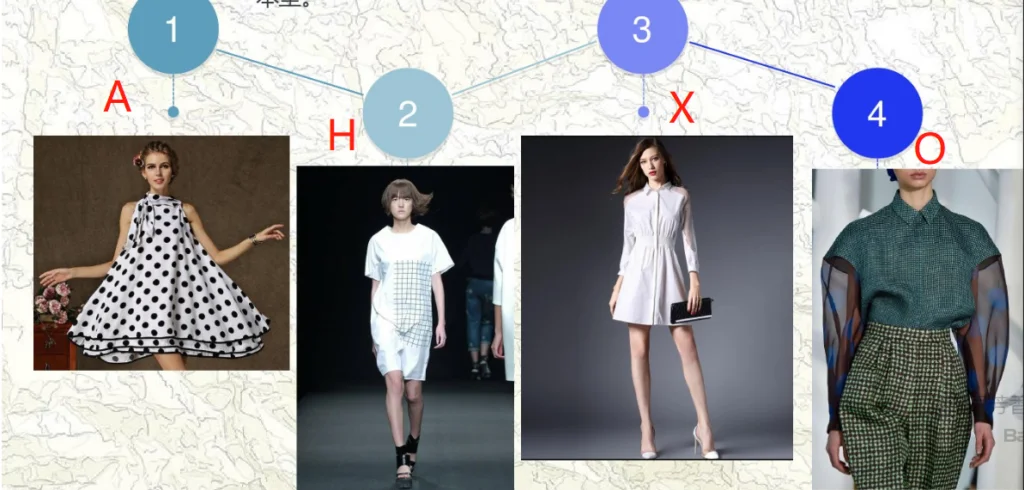

There are four basic types of clothing pattern design: A, H, X, and O, as shown in the figure below.

Type A is also called triangle, ladder type, A-type clothing has narrow top and wide bottom, such as cloak, flared skirt, flared pants, etc., which is lively and chic;

Type H is also called cabinet type, box type, square type. The width of the shoulder, waist and hem of the H-shaped garment is basically the same, such as straight skirts, straight pants, dresses, straight sinking shirts, etc., showing solemnity and simplicity;

X-type clothing has wide shoulders, tight waists, and bottom hem of the dress, with obvious undulations in outer contours;

O-type clothing has no obvious edges and corners on the outer contour, and is looser, giving people an implicit and gentle aesthetic feeling;

We have a professional design team that can design clothes according to the needs of customers, but in general, customers are very clear about what they want, that is, customers will provide the version of clothing, or provide patterns, we only need to follow the customer’s version of clothing or patterns or design draft and some modified comments.

- Making paper sample

If the customer only provides the version of clothing or design draft, we can make the pattern according to the customer’s version of clothing or design draft, and the pattern is made by a professional pattern master..

- produce template

The process of produce a template

First, we make the front page according to the version of clothing, design drafts provided by the customer, or the pattern made by our pattern master. Second, we always pay attention to the delivery time required by the customer, control the delivery date, and confirm the fabric accessories with the customer as soon as possible (usually we are based on the style of the clothes to recommend fabric accessories to customers). After confirmation, the amount of fabric accessories should be calculated according to the version of the clothing or the pattern and the cloth seal of the fabric. And the next thing is to purchase, arrange proofing, and check whether it meets the customer’s requirements after sampling.

Quality control of the model:

First we check whether the overall shape is reasonable by trying on. Take T for example, check whether the collar is round and smooth, whether the left and right clamps are symmetrical, whether the length of the left and right sleeves are the same, whether the feet are aligned, whether there are defects in the lathe. And check the color cut whether there is a color difference between the pieces, if there is tolerance, it depends on whether the length of the tolerance is consistent and symmetrical. These are all problems that can be seen with the naked eye. Second, we compare the customer’s version of the clothing, design draft or pattern and revised comments, and check the size and the method of production; In addition, even if the samples meet all the customer’s requirements, we have to check whether some parts are not in accordance with common sense. For example, the customer requires that the size of the armhole is 17cm, but the fabric used in the clothes is not elastic and the upper body is tight. It is necessary to advise the customer to modify the size;

We want to emphasize the size again: because people in different countries have different body shapes, the clothes must be produced in strict accordance with the requirements of foreign customers in terms of size, instead of adjusting the size without authorization when it feels that the size of the clothes is larger than that of the Chinese. It is wrong to produce according to one’s own subjective opinions. For example, some clothing, foreign customers need it to be relatively long, such as the Muslim clothing abaya, which is very long in length and touches the floor.

The shrinkage of fabrics should also be considered: the shrinkage of materials includes washing shrinkage, ironing shrinkage, and hot ironing shrinkage. Therefore, corresponding treatment should be carried out when drawing the garment structure.

There is also the thickness of the fabric: For example, silk fabrics are relatively light and soft, and wool fabrics are thick and firm. Therefore, when cutting silk fabrics, the diagonal yarns should be shortened and relaxed appropriately.

These experiences are summed up by us in helping customers sourcing garments in Guangzhou for many years.

Control costs

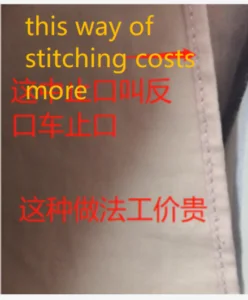

If the customer wants to reduce the cost of clothes, we must consider reducing the cost from the fabric and the workmanship. For example, the cheap fabric of the source must have the same quality. The same fabric is sold at different prices at different stalls in the fabric market, so we can go to Guangzhou fabrics in the wholesale market, looking for cheap sourcing; in terms of workmanship, for example, the method of front edge cutting is changed to the method of edge cutting and then crimping to reduce the cost of work. The two methods are the same in appearance, but there are differences inside as the picture below, so we will give customers suggestions for their choices. In terms of workmanship, there are many ways to save costs by changing the method. For example, where there are bundles, you can change it into the original cloth folded in or out and then pressed the line. The cost of this approach is lower than that of bundled strips. The next thing we do is to communicate with customers, send the front page, and follow up to see if the customer has revision comments. If revisions are needed, continue to arrange for modification samples. If there are no revisions, follow up and urge customers to place orders.

Clothing accessories are also a very important part. If the quality of the accessories is too poor, it will affect the quality of the whole clothes. For example, a suitable button can improve the quality level. To find the best cost-effective accessories.

- Production

After the front page is approved, the customer will place a production order. After receiving the order, you must first verify whether the customer’s delivery date can be met (by verifying the time when the fabric accessories can arrive in the warehouse, and the production factory’s order situation to determine the delivery date, give it an extra week or so in case something special happens), and then negotiate the delivery date with the customer to reach an agreement. After the delivery date is negotiated, find the Marker tailor to calculate the amount of each piece of bulk goods, and calculate the total amount of fabric required for the bulk goods based on the amount and the order quantity. Pay attention to add 8-15 points of loss , After calculating the dosage, place a purchase order to purchase fabrics and accessories, and follow up to control the arrival time of them. After the fabrics are returned to the warehouse, personnel should be arranged to inspect each piece of fabric. Many times the fabric will have problems, such as drawn yarn, indentation or serious color difference and too many stains. If the problem is so severe that the fabric can’t be used,we need to contact the fabric stall to return; if the clothing is of higher grade, the bulk fabric must undergo professional testing for various properties (like SGS testing company), such as the shrinkage of the fabric, fastness to light, color fastness to dry rubbing, color fastness to perspiration, pilling coefficient, anti-friction degree, breaking strength, tearing strength, etc. Among them, the color fixation, no matter what grade we have to check the clothes ourselves. Cut a piece and soak it in a water cup for a period of time, or cut a piece to wash by hand to see if there is any color loss. If there is any color loss, we need to contact the stall to return it; and sometimes the fabric will appear. Shortcode (the cloth at the Guangzhou fabric stall is 100 meters full of meters, but it is actually only 90 meters. This situation is called short code or short meters), and the gap is too large (you have already followed it before buying the cloth. After negotiating the stall, the gap of the fabric is 97%, which means that 100 meters is only 97 meters, but the charge is 100 meters. If the cloth of 100 meters is found to be only 90 meters, then it is 90% of the gap. Please contact the stall. Make up 7 meters, or refund the difference); or sometimes the width of the fabric is much smaller than the negotiated width. If the width is smaller, the amount will increase, or it may be impossible to cut;

After all the surface accessories are prepared, we arrange factory production. The bed cutter cuts the fabric according to the marker produced by the marker master, and follows up whether the amount of the cut material exceeds or is less than the amount calculated by the marker master. If so, Check with the marker master to find out the reason. Some customers request to send pre-production samples, then arrange the factory to do the pre-production sample confirmation before cutting bulk fabrics. Note: There may be unevenness in bulk fabrics, you must carefully contrast the colors, and cut the whole piece in the same color so that there is no color difference between different cut pieces on the same garment;

The next step is to supervise the production and follow up the process. The front page of the ship will be sent to the customer one week before the shipment, and the ship can be shipped after confirmation. Note that the front page of the ship should also be carefully checked. The method is the same as the above. Check the version, manual, and practice. The size, color difference, etc., control the delivery date to ensure that the goods can be shipped on time with quality.

- Check goods and packaging

The tail inspection must also be strict. After the bulk goods are completed, the merchandiser needs to spot-check each code segment. The inspection method is the same as the above. After the confirmation of the merchandiser, the tail commodities inspection shall be arranged. It is important to pay attention to the packaging and remember to put moisture-proof beads and moisture-proof paper for shipping. In addition, we must also consider how to reduce the cost of clothing packaging in international transportation, such as reducing packaging space.

Hope the above experience sharing can help you. Thanks for reading!